QUALITY CONTROL

prefessional inspection on each station, all of those progress

make sure our led strip with reliable quality.

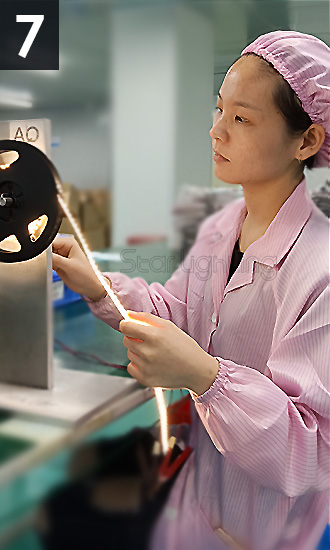

Apperance QC

PCB-Clear

QC Light

Chip QC

Color Uniform Checking

3M Tape Checking

Rolling QC

Final QC Testing

1.All incoming raw materials must undergo strict QC and comparison before they can go into the warehouse to ensure the quality of raw materials.

2.All the led before going to SMT progress need dehumidified. It will be baked for 12 hours before production (to prevent the led glue cracking and failing when go through the high reflow oven)

3.All LED strip are standardized by brand Siemens SMT matchine from Japan. After SMT progress, there is QC checking for the order of all the components, whether they are placed neatly.(Avoid irregular placement)

4.If the peak temperature setting of high reflow oven is too low, it is easy to produce cold junctions and insufficient melt of the soldering paste.

while higher the preheating temperature, the faster the speed, the easier it is to form tin beads (Ensure that the solder paste is completely melted and there is no false soldering or false soldering)

5.All the led strip after high reflow oven, need do first test, light on by full current and half current, half current can easy to find out the led which already have damaged, which can’t be disguished by full current test.

6.All the led strips are welded to the length required length. Professional welding workers ensure the smoothness, and stability of the solder joints, and QC again.

7.Aging test: All strips are tested for 8 hours of aging after appearance cleaning

8.Small current QC: detect whether there are hidden quality hazards such as leakage (Adoid dead LED which had been damaged by static after short-term use, to ensure the lifetime of LED strip)

9.Light on strip normally, Check the color consistency through white acrylic as the reference object (Avoid inconsistent colors when customer using it)

10.Shake checking: avoid the false soldering, better quality control, less trouble will have after delivery.

11.After paste 3m tape, the strip will do FQC again.